Description

The trains of balls are designed to a contact angle of 45° which enables it to bear an equal load in radial, reversed radial and lateral directions. Therefore, it can be applied in any installation direction. Furthermore, MSA series can achieve a well balanced preload for increasing rigidity in four directions while keeping a low frictional resistance. This is especially suit to high precision and high rigidity required motion.

The patent design of lubrication route makes the lubricant evenly distribute in each circulation loop. Therefore, the optimum lubrication can be achieved in any installation direction, and this promotes the performance in running accuracy, service life, and reliability.

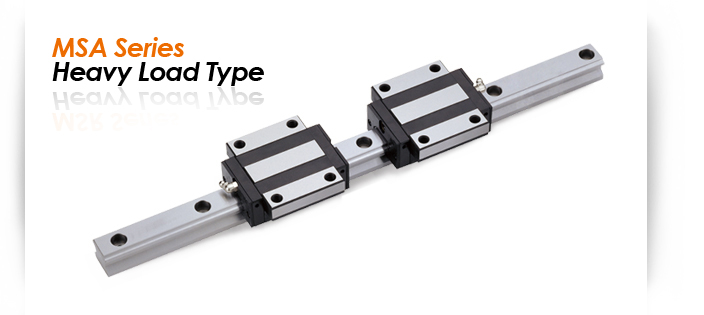

PMI MSA Series Heavy Load Type MSA-S

MSA S/LS

Note: The basic dynamic load rating C of ball type is based on the 50 km for nomonal life.

The conversion between C for 50 km and C100 for 100 km is C=1.26 x C100.

Note*: Single: Single carriage / Double: Double carriages closely contacting with each other.

| Unit:mm |

| Model No. | External dimension | Carriage dimension | |||||||||||||

| Height H |

Width W |

Length L |

W2 |

H2 |

B |

C |

S × l | L1 | T | N | G | K | d1 | Grease Nipple | |

| MSA 15S | 28 | 34 | 56.3 | 9.5 | 4.2 | 26 | 26 | M4 x 5 | 39.3 | 7.2 | 8.3 | 7 | 3.2 | 3.3 | G-M4 |

| MSA 20S MSA 20LS |

30 | 44 | 72.9 88.8 |

12 | 5 | 32 | 36 50 |

M5 x 6 | 51.3 67.2 |

8 | 5 | 12 | 5.8 | 3.3 | G-M6 |

| MSA 25S MSA 25LS |

40 | 48 | 81.6 100.6 |

12.5 | 6.5 | 35 | 35 50 |

M6 x 8 | 59 78 |

10 | 10 | 12 | 5.8 | 3.3 | G-M6 |

| MSA 30S MSA 30LS |

45 | 60 | 97 119.2 |

16 | 8 | 40 | 40 60 |

M8 x 10 | 71.4 93.6 |

11.7 | 10 | 12 | 6.8 | 3.3 | G-M6 |

| MSA 35S MSA 35LS |

55 | 70 | 111.2 136.6 |

18 | 9.5 | 50 | 50 72 |

M8 x 12 | 81 106.4 |

12.7 | 15 | 11.5 | 8.6 | 3.3 | G-M6 |

| MSA 45S MSA 45LS |

70 | 86 | 137.7 169.5 |

20.5 | 10 | 60 | 60 80 |

M10 x 17 | 102.5 134.3 |

16 | 20 | 13.5 | 10.6 | 3.3 | G-PT1/8 |

| MSA 55S MSA 55LS |

80 | 100 | 161.5 199.5 |

23.5 | 13 | 75 | 75 95 |

M12 x 18 | 119.5 157.5 |

18 | 21 | 13.5 | 8.9 | 3.3 | G-PT1/8 |

| MSA 65S MSA 65LS |

90 | 126 | 199 253 |

31.5 | 15 | 76 | 70 120 |

M16 x 20 | 149 203 |

23 | 19 | 13.5 | 8.9 | 3.3 | G-PT1/8 |

| Model No. | Rail dimension | Basic load rating | Static moment rating | Weight | ||||||||||

| Width W1 |

Height H1 |

Pitch P |

E std. |

D × h × d |

Dynamic C kN |

StaticCo kN |

Mp kN-m |

MY kN-m |

MR kN-m |

Carriage kg |

Rail kg/m |

|||

| Single* | Double* | Single* | Double* | |||||||||||

| MSA 15S | 15 | 15 | 60 | 20 | 7.5 x 5.3 x 4.5 | 11.8 | 18.9 | 0.12 | 0.68 | 0.12 | 0.68 | 0.14 | 0.18 | 1.5 |

| MSA 20S MSA 20LS |

20 | 18 | 60 | 20 | 9.5 x 8.5 x 6 | 19.2 23.3 |

29.5 39.3 |

0.23 0.39 |

1.42 2.23 |

0.23 0.39 |

1.42 2.23 |

0.29 0.38 |

0.3 0.39 |

2.4 |

| MSA 25S MSA 25LS |

23 | 22 | 60 | 20 | 11 x 9 x7 | 28.1 34.4 |

42.4 56.6 |

0.39 0.67 |

2.20 3.52 |

0.39 0.67 |

2.20 3.52 |

0.48 0.63 |

0.52 0.68 |

3.4 |

| MSA 30S MSA 30LS |

28 | 26 | 80 | 20 | 14 x 12 x 9 | 39.2 47.9 |

57.8 77.0 |

0.62 1.07 |

3.67 5.81 |

0.62 1.07 |

3.67 5.81 |

0.79 1.05 |

0.86 1.12 |

4.8 |

| MSA 35S MSA 35LS |

34 | 29 | 80 | 20 | 14 x 12 x 9 | 52.0 63.6 |

75.5 100.6 |

0.93 1.60 |

5.47 8.67 |

0.93 1.60 |

5.47 8.67 |

1.25 1.67 |

1.45 1.9 |

6.6 |

| MSA 45S MSA 45LS |

45 | 38 | 105 | 22.5 | 20 x 17 x 14 | 83.8 102.4 |

117.9 157.3 |

1.81 3.13 |

10.67 16.95 |

1.81 3.13 |

10.67 16.95 |

2.57 3.43 |

2.83 3.7 |

11.5 |

| MSA 55S MSA 55LS |

53 | 44 | 120 | 30 | 23 x 20 x 16 | 123.6 151.1 |

169.8 226.4 |

3.13 5.40 |

17.57 28.11 |

3.13 5.40 |

17.57 28.11 |

4.50 6.00 |

4.12 4.91 |

15.5 |

| MSA 65S MSA 65LS |

63 | 53 | 150 | 35 | 26 x 22 x 18 | 198.8 253.5 |

265.3 375.9 |

6.11 11.84 |

33.71 57.32 |

6.11 11.84 |

33.71 57.32 |

8.36 11.84 |

6.43 8.76 |

21.9 |

As a professional Linear Motion Guide supplier, we are mainly responsible for the global sales and technical services of HIWIN products. If you have any demand, you can directly contact us.